MANUFACTURING SAFETY

AUDIT CHECKLIST

Download our free PDF Safety Audit Form, or Get a Live Demo to discover how we incorporated this checklist into an easier, faster mobile app with visual assistance to guide the inspection. Customize inspections and work instructions to your exact equipment and manufacturing processes to boost safety and compliance with regulations.

Get Live Demo

Ensuring Manufacturing Safety

With almost one half million injuries annually in manufacturing, ensuring safety is paramount, not just for compliance with regulations, but for the well-being of employees and the efficiency of operations. An effective safety audit checklist serves as a roadmap to identify potential hazards, enforce safety measures, and cultivate a culture of safety within the workplace.

Outlined here are items related to Manufacturing Safety Audits, designed to address common questions and concerns:

What is a Manufacturing Safety Audit?

A Manufacturing Safety Audit is a systematic examination of a manufacturing facility’s operations and procedures to ensure compliance with safety regulations and to identify potential hazards. The audit aims to prevent accidents and injuries and ensure a safe working environment.

How often should Safety Audits be conducted?

The frequency of Safety Audits can vary depending on the specific regulations of your industry and region, but it’s generally recommended to conduct them at least annually. High-risk areas may require more frequent audits, and it’s also wise to perform an audit whenever there are significant changes to operations, equipment, or processes.

Who should perform the Safety Audit?

Safety Audits should ideally be conducted by a team that includes individuals with expertise in safety protocols, as well as representatives from various departments within the facility. External auditors can also be brought in for an unbiased assessment.

What should be done if a hazard is identified?

If a hazard is identified, it should be documented, and immediate steps should be taken to mitigate the risk. This may involve making physical changes, adjusting procedures, or providing additional training to employees. A follow-up should be scheduled to ensure the hazard has been adequately addressed.

How can employees contribute to the safety audit process?

Employees can play a crucial role in the safety audit process by being proactive in reporting potential hazards, participating in safety training, and adhering to all safety protocols. Encouraging a culture where safety concerns are openly communicated can significantly enhance the effectiveness of safety audits.

What safety trainings are required to be completed?

OSHA, the Occupational Safety Health Administration, publishes regulations regarding safety in the workplace and does require specific training to be completed for manufacturing companies. Specific training requirements vary based on industry, job functions and workers’ exposure to specific tasks, equipment or materials. OSHA publishes a training guide which can be found here. In addition to OSHA, which is a federal agency, individual states may have state functions that regulate workplace safety in that state.

What is a Manufacturing Safety Audit?

How often should Safety Audits be conducted?

Who should perform the Safety Audit?

What should be done if a hazard is identified?

How can employees contribute to the safety audit process?

What safety trainings are required to be completed?

Essential Elements of a Safety Checklist

Stay Compliant and Save Time - Go Digital

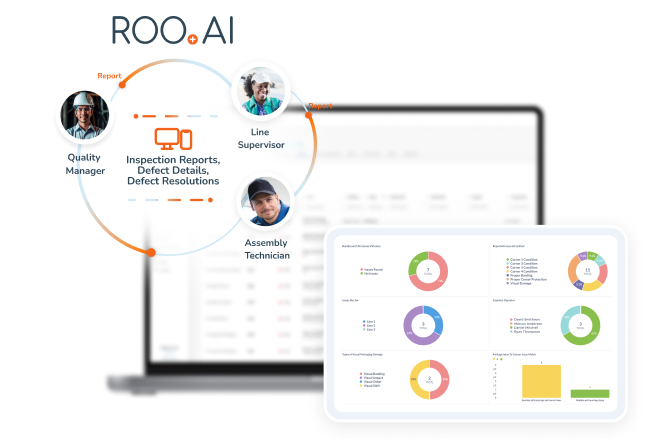

ROO.AI Improving Manufacturing Safety and Quality

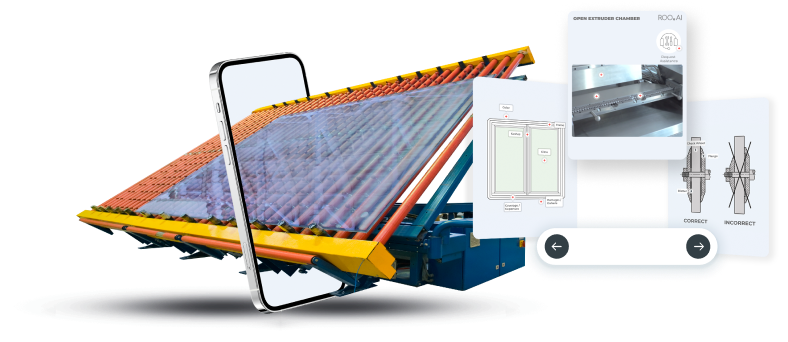

Simplify Inspections & SOPs

Move beyond traditional paper forms and lists with an innovative, visual-based solution that’s accessible anytime, anywhere. This user-friendly, intuitive approach enhances efficiency across all skill levels, visually guiding users through inspections and providing safety instruction and micro-training access during inspections.

Drive Accuracy & Defect Visibility

Ensuring adherence to standards in safety and quality checks, even amidst the diversity of manufacturing processes, is a key to effective compliance. Automated collection of inspection data, along with images and video, is instantly available, enabling swift identification of safety hazards that can threaten workers or affect process or product quality.

Automate Risk Management & Audit Processes

Reduce the complexities and effort of risk and audit oversight. Achieve clear insights into safety issues, and resolution activities and timelines. Meanwhile, ROO.AI automatically compiles a comprehensive log of all inspections, corrective actions and verification for every facility or asset examined which can be easily viewed online or downloaded in various formats.