Quality Inspection Software

Faster Defect Resolution

Unique, visual inspections and LPAs cut time and increase compliance and defect detection, while providing instant visibility to deficiencies for faster corrective action by quality and production teams.

Improve Quality by Replacing Paper on the Frontline

Upskill

Inspect

Automate

Trace

Quality Drives Industry's

Best Lifetime Value

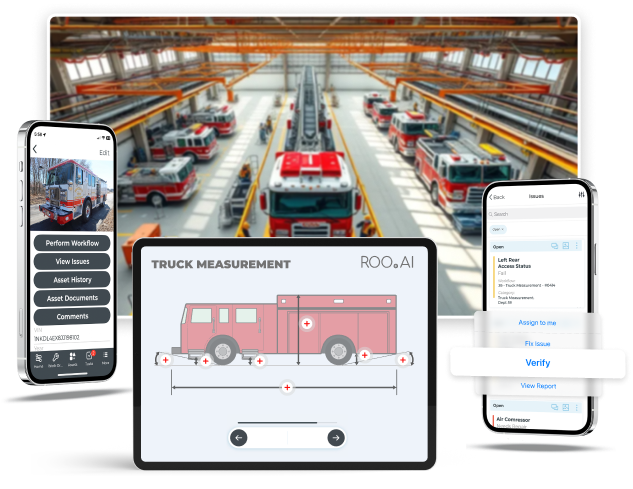

End To End Digitalized Quality Platform

For a Connected Frontline

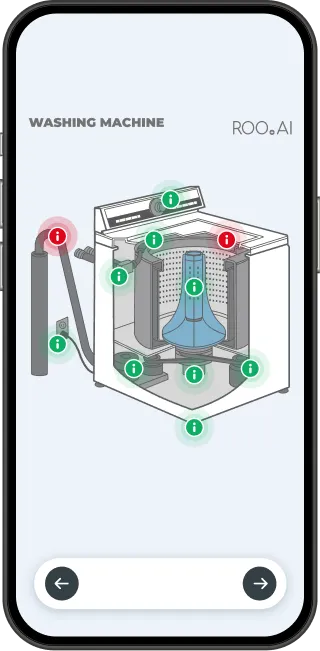

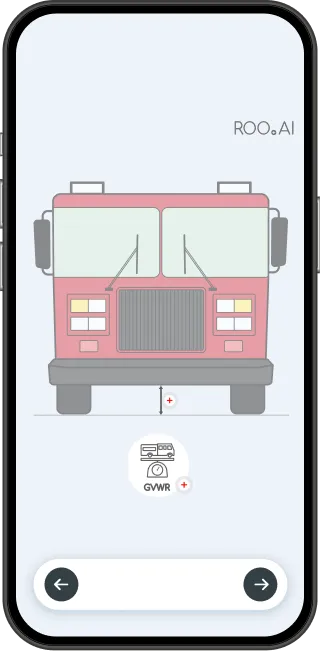

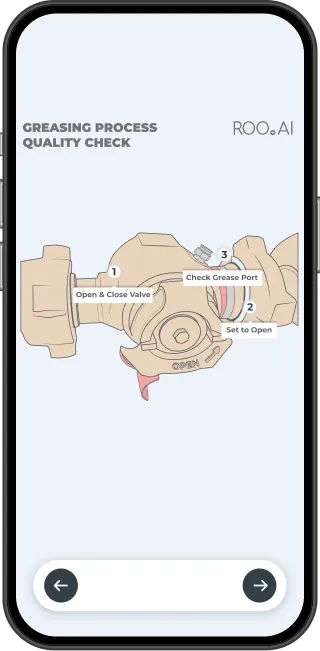

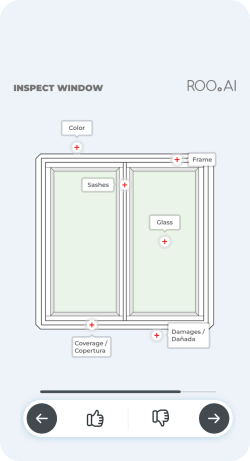

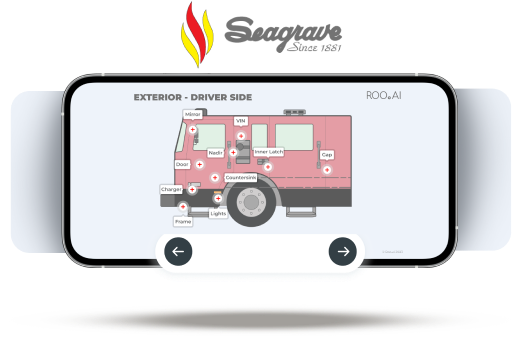

Cut Inspection Time, Drive Standards

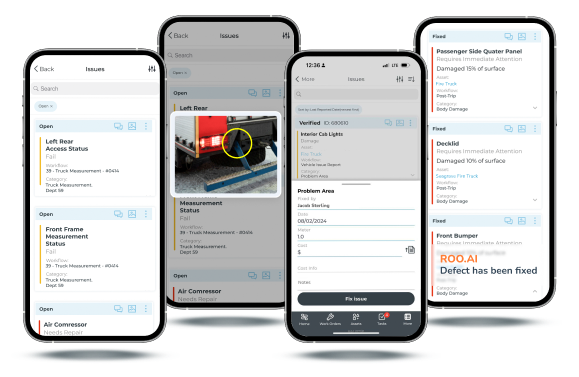

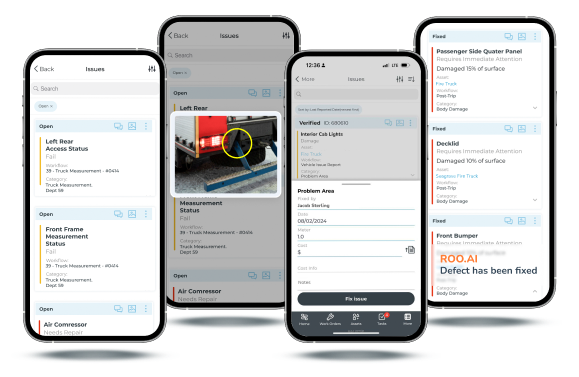

Intuitive, visual and mobile native, ROO.AI cuts inspection times up to 70%, while increasing compliance and accuracy resulting in faster defect resolution and increased defectless production.

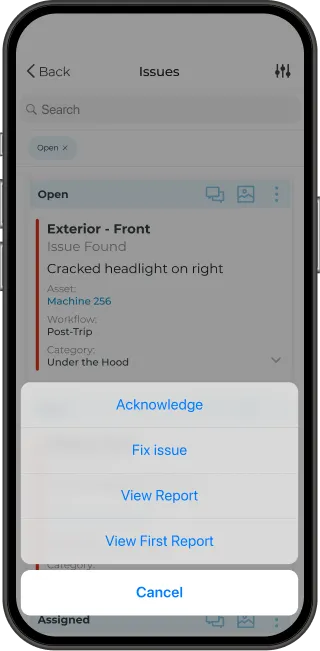

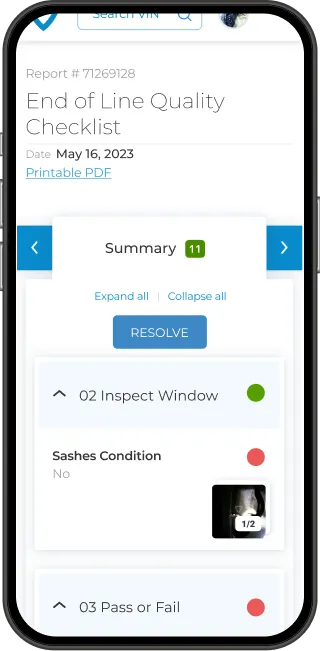

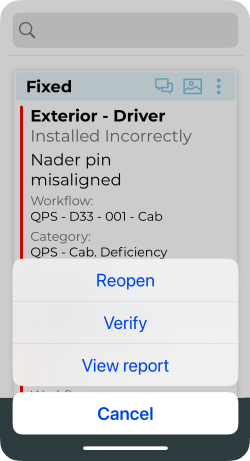

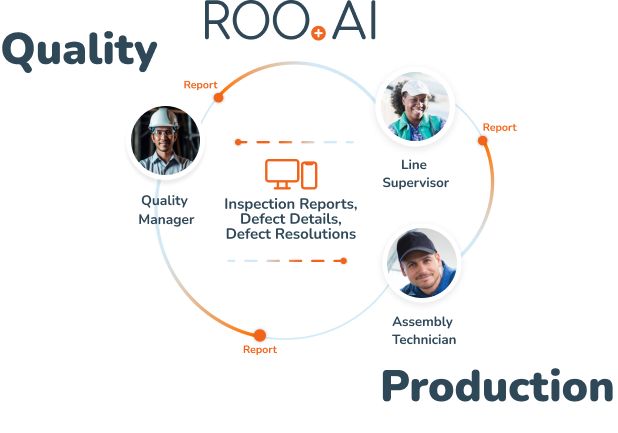

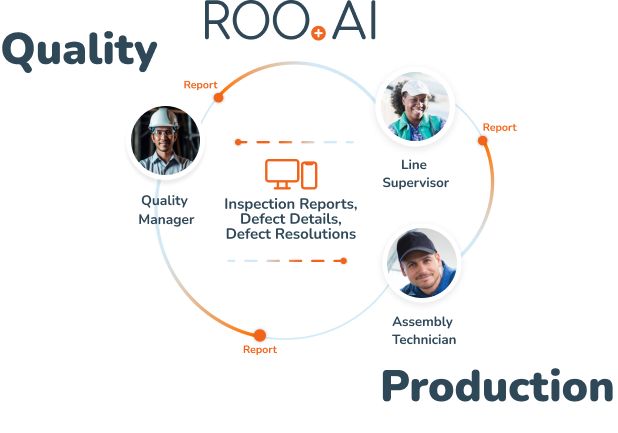

Take Immediate Corrective Action

With instant visibility to defects, enable quality and production teams to collaborate more effectively through alerts, comment streams, images, videos, tasks and shared issue tracking from defect detection through resolution.

Automate Defect to Repair Processes

Cut production cycles and automate the path to defectless product with a built-in, closed loop defect resolution module. Make defects instantly visible to production teams, enable on the spot documentation of fixes and alerts to quality teams for verification.

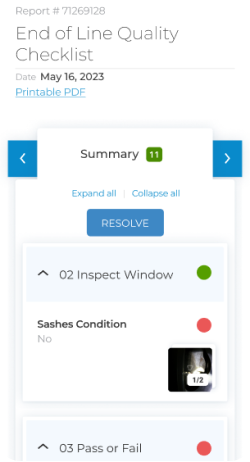

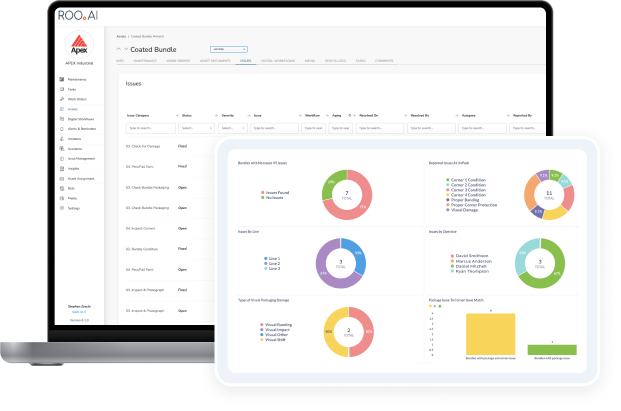

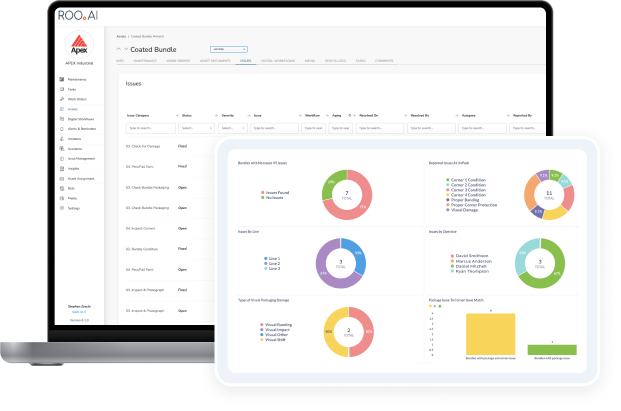

Traceability and Auditability

Gain real time visibility to quality issues, department and individual performance, and automate the traceability of defects and resolutions. Make generation of quality reports and KPIs hassle free with customizable dashboards.

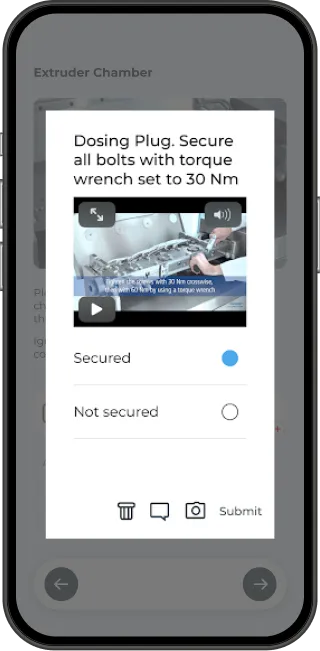

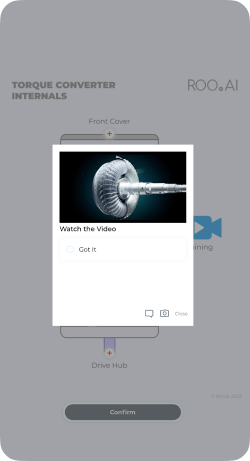

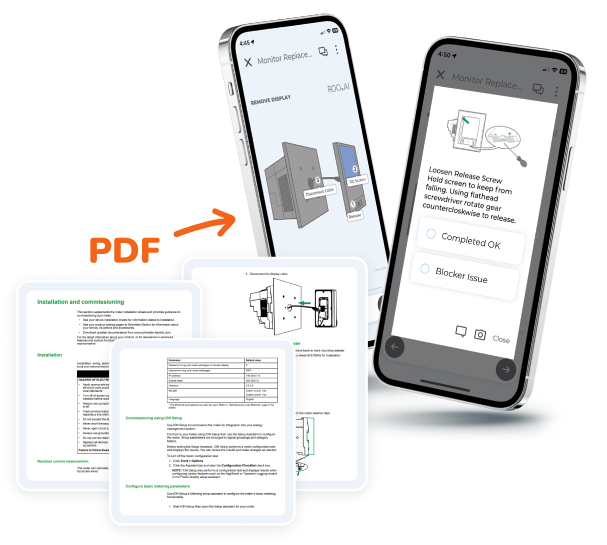

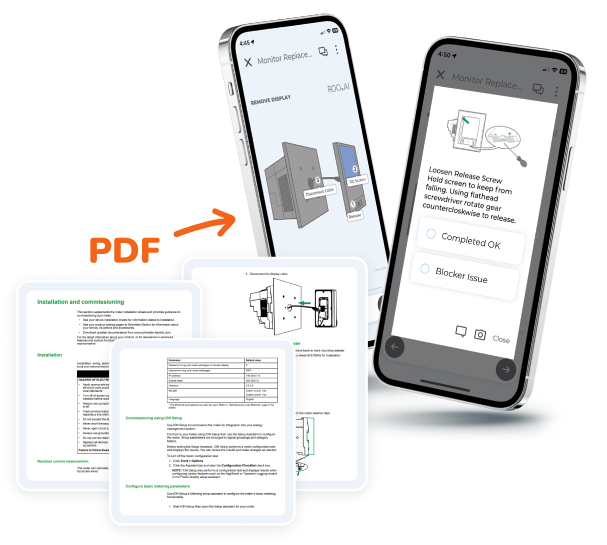

Use AI to Digitalize Faster, Work Smarter

Get started quickly with minimum impact to quality and production resources. ROO.AI can convert existing forms, checklists or even videos into powerful and effective digital workflows. Then use AI Agents to assist workers on the spot, in process with work instruction or recommended fixes to improve performance and boost quality.