Easier, More Efficient

Production, Quality Control and Equipment Maintenance

Upskill your workforce, boost productivity, ensure compliance and drive procedural adherence by replacing paper forms and checklists with digital work instructions, quality inspections and equipment set up and maintenance.

Ensure The Job’s

Done Right

Automate Defect

to Repair

Reduce Non

Productive Time

Replacing Paper Improves Frontline Productivity & Quality

Upskill

Inspect

Automate

Trace

Quality Drives Industry's

Best Lifetime Value

An End to End Connected Worker Platform

that Boosts Frontline Workforce Performance

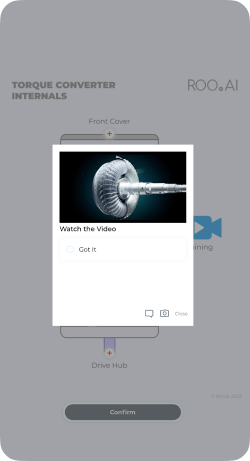

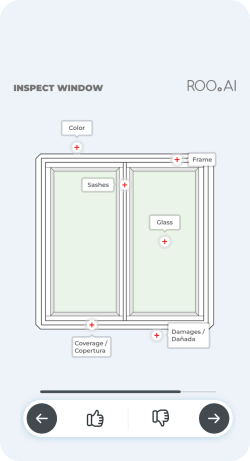

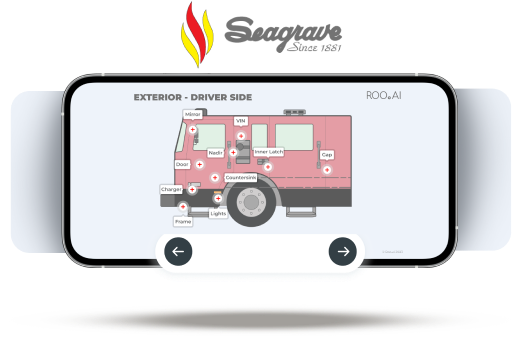

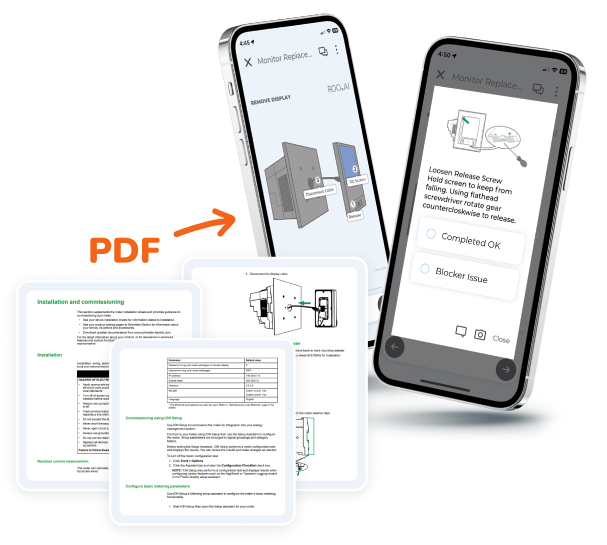

Simplify Inspections & SOPs

Leave paper forms and checklists for a breakthrough visualization approach - online and offline - that’s intuitive and frontline friendly to improve quality and productivity regardless of skill level.

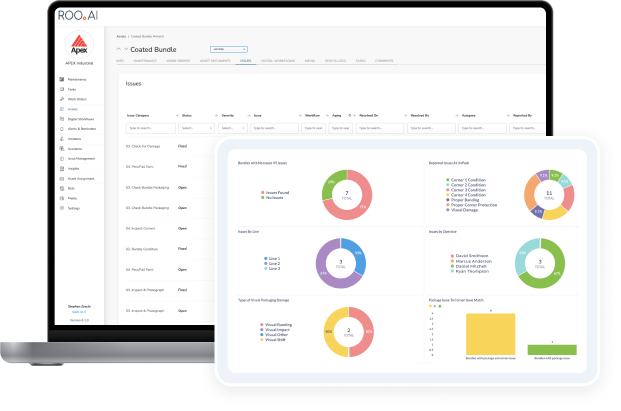

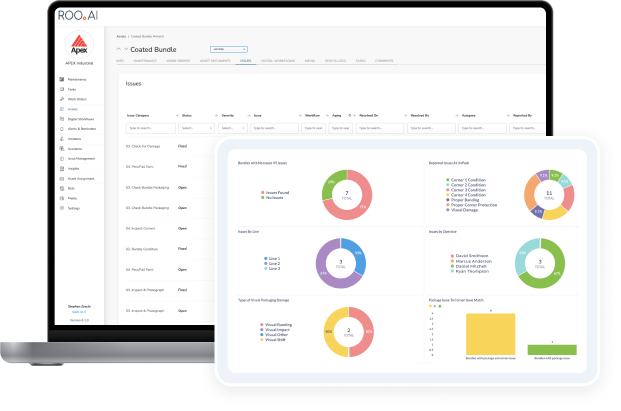

Drive Accuracy & Defect Visibility

Ensure сompliance and accuracy for quality inspections despite the variability in MTO manufacturing, and gain instant access to quality data to spot issues and take corrective action faster.

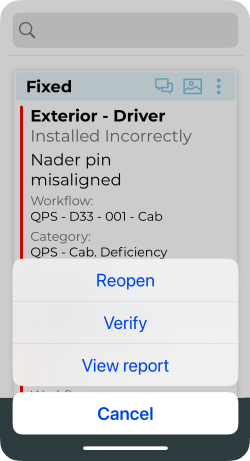

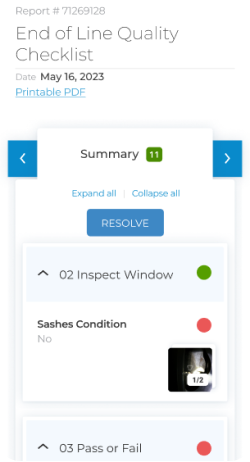

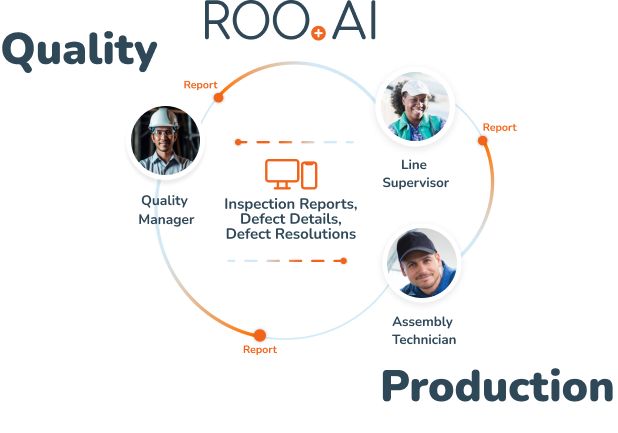

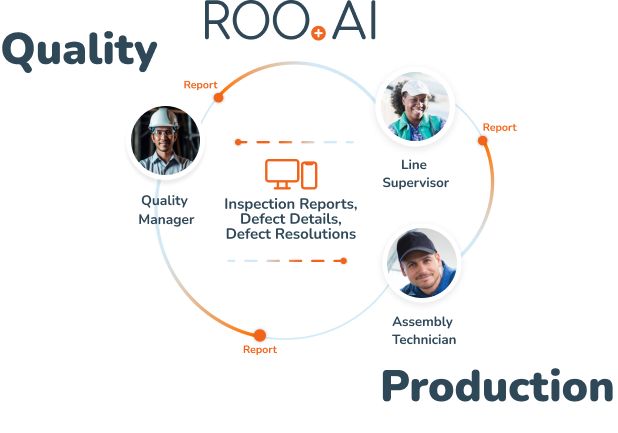

Automate Defect to Repair Processes

Cut production time and automate the path to defectless product with a closed loop process that instantly makes defects visible to production with images and video annotation. Make fixes visible to quality staff for in-process verification.

Traceability And Auditability

Simplify risk management and audit management. Gain visibility to quality issues, department and individual performance and time to resolution, while ROO.AI automatically assembles a unique record of all activity for each unit inspected.

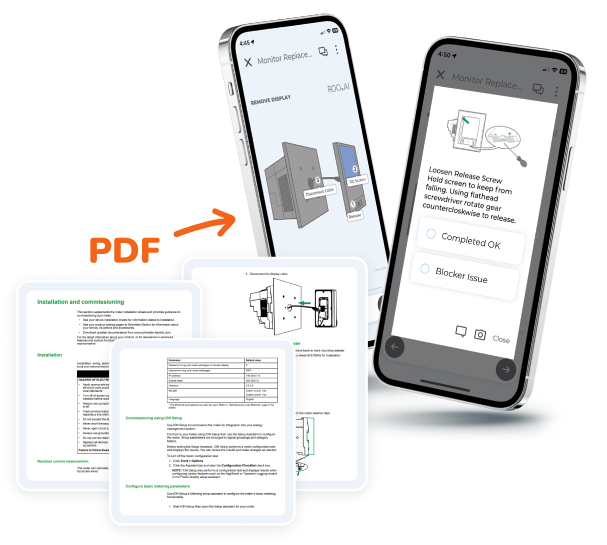

Use AI to Digitalize Faster, Work Smarter

Get started quickly with minimum impact on quality and production resources. ROO.AI can convert existing forms, checklists or even videos into powerful and effective digital workflows. Then use AI Agents to assist workers on the spot, with work instructions or recommended fixes to improve performance and boost quality.

A Custom Fit

for MTO

Manufacturers

Tailor Your Inspections

A Mobile & Cloud Platform