FREE 5S AUDIT

CHECKLIST

Download our free PDF 5S audit form or get a live demo to discover how we incorporated this checklist into an easier, faster mobile app with visual inspection assistance.

Get Live Demo

Outlined here are items related to 5S Audit, designed to address common questions and concerns:

What is 5S Audit?

The 5S framework is a systematic approach primarily used in the manufacturing sector to create organized, clean, and efficient workspaces. This method promotes a culture of continuous improvement that enhances productivity and safety. The 5S audit checklist serves as a vital tool in this process, helping businesses maintain the discipline needed to ensure each element of 5S is properly implemented.

Understanding 5S

- Overview of 5S Principles: The five pillars of 5S – Sort, Set in order, Shine, Standardize, and Sustain – provide a methodology for organizing spaces that reduce waste and optimize productivity.

- History and Origin of 5S: Originating in Japan as part of lean manufacturing systems, the 5S methodology was developed to streamline environments in a way that promotes work efficiency.

Benefits of Implementing 5S Audits

- Remove non-value-adding activities from their operations.

- Streamline work processes and protocols to enhance efficiency.

- Identify and address potential safety risks in the workplace.

- Sustain high levels of cleanliness and organization in work areas.

- Boost employee involvement and commitment by engaging them in 5S initiatives.

5S Audit Procedures

- How to Conduct a 5S Audit: Conducting a 5S audit involves reviewing each area against established standards and documenting the findings.

- Roles and Responsibilities in a 5S Audit: Clearly defined roles and responsibilities ensure that audits are thorough and that improvements are consistently applied.

- Frequency of 5S Audits: Regular audits, whether daily, weekly, or monthly, are crucial to prevent backsliding into old habits.

What is 5S Audit?

Understanding 5S

Benefits of Implementing 5S Audits

5S Audit Procedures

Essential Elements of 5S Audit Checklist

Stay Compliant and Save Time - Go Digital

ROO.AI Improving Manufacturing Safety and Quality

Easier, Faster 5S Audit Procedures

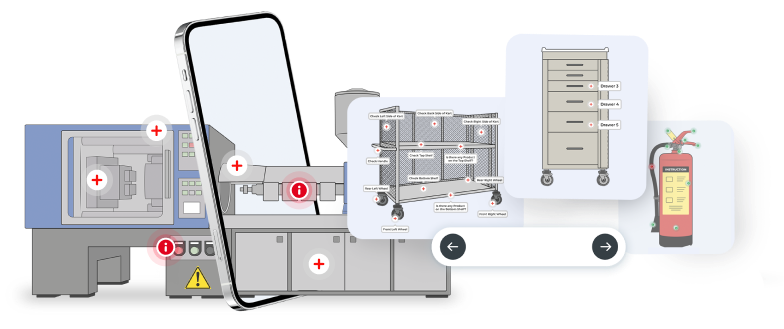

Empower EHS staff and workers to more quickly, easily and accurately conduct 5S audits than they did with outdated paper forms and checklists. Adopting a cutting-edge, visual-based system that’s intuitive and user-friendly improves efficiency for all proficiency levels by visually navigating users through inspections and providing instant access to safety instructions and micro-training during the process.

Incorporate 5S Training into Onboarding Processes

Integrate 5S methodology seamlessly into new employee onboarding to foster an immediate understanding and implementation of workplace organization and efficiency standards. This strategic inclusion ensures that from day one, workers are guided with the knowledge and skills necessary to contribute to a productive and safe work environment.

Enhance Accuracy and Highlight Defects

Maintain strict adherence to safety and quality standards across diverse manufacturing processes. The automated gathering of inspection data, supplemented with images and videos, allows for the immediate recognition of safety risks and quality issues, ensuring that they are quickly addressed to protect workers and maintain product integrity.