The data center construction industry sits at the intersection of rapid digitization, artificial intelligence (AI), and global demand for resilient, scalable computing. Data center construction is booming, and economist Alan Furman of Harvard estimated that along with tech investment it may be responsible for as much as 50% of US GDP growth in the last year.

As enterprises, hyperscalers, and cloud providers race to deliver capacity, data center construction companies are adapting to a broad set of emerging data center trends — from stringent data center compliance and regulations to power grid constraints, labor shortages, and sustainability pressures. To help address the implications, owners, construction company executives, contractors, and frontline leaders need a clear focus on effective planning, job site execution, and workforce performance to address the critical elements of building modern data centers

Why Data Center Construction is Different Today

AI Boom & Increasing Demand

One of the most consequential data center construction trends is the explosive growth in AI-driven data center build outs. Organizations deploying AI and AI-infrastructure are driving demand for facilities with ultra-high power density. This sharp increase not only influences data center design and infrastructure requirements but also affects data center construction costs, which are rising as a result.

Power Constraints & Infrastructure Delays

Power remains one of the most significant risks to project delivery. Securing utility interconnection agreements and upgrades is now a central part of data center planning, especially in regions with grid capacity limits. Delays at the utility level can ripple through project schedules and budgets, making electrical infrastructure planning a critical component of data center project management.

Sustainability & Efficiency

Today’s data centers are expected to align with data center sustainability goals. This includes improving Power Usage Effectiveness (PUE), integrating renewable energy sources, and managing water and carbon footprints. Sustainability considerations must be baked into early data center design and verified through construction and commissioning.

Complex Compliance & Regulations

With increasing scrutiny around electrical safety, fire protection, environmental impact, and energy efficiency, adherence to data center compliance and regulations is more complex than ever. Navigating local, regional, and national codes adds risk to the schedule and reinforces the need for experienced compliance professionals within project teams.

Labor & Skills Shortages

Across the industry, there’s a lack of skilled talent capable of building and commissioning high-performance data center facilities. This impacts not only hiring for construction companies but also the data center construction services ecosystem as a whole, from subcontractors to specialized technical trades.

Supply Chain Challenges

Long lead times for critical equipment — from construction equipment to facility equipment such as UPS systems, generators, and precision cooling — remain a persistent challenge. Effective logistics and procurement strategies are essential to keep projects on schedule and control data center construction costs.

Workforce Challenges in Modern Data Center Construction

Labor & Skills Shortages

Insufficient talent pools, particularly for specialized electrical and mechanical work, continue to impact delivery. This shortage emphasizes the importance of early workforce planning and strategic partnerships with training organizations.

Technical Complexity

Installing and testing redundant power paths, precision cooling, network fabrics, and building security and automation systems requires both technical know-how and rigorous execution discipline.

Trade Coordination

Complex job sites demand proactive coordination across multiple contractors and subcontractors. Without it, clashes in sequence and schedule are almost inevitable.

Safety Risk Exposure

The combination of high-energy infrastructure and tight timelines can elevate safety risk if not managed proactively. Safety must be integrated into daily operations, not treated as an administrative task.

Aggressive Schedules

Clients and developers often push aggressive delivery timelines to meet business objectives. Smart planning, risk buffers, and adaptive project management methodologies help teams deliver without compromising quality.

Best Practices that Drive Construction Execution Success and Job Site Operations that Work

Data center construction succeeds or fails at the intersection of project management discipline and frontline execution. Requiring more than conventional commercial building projects, the current AI-driven demand for data centers combines compressed schedules, state of the art high energy infrastructures, massive capital exposure, and zero-tolerance performance requirements. That means execution models must be purpose-built for speed, precision, and reliability.

The most successful data center construction companies treat project controls, workforce coordination, and quality systems as a single integrated operating system rather than disconnected functions.

1. Run Integrated, System-Driven Project Management

Best-in-class data center projects are managed around systems, not spaces. Power, cooling, controls, and network infrastructure define the true critical path — not drywall or finishes.

Effective project management practices include:

- Maintaining trade-level master schedules that reflect real installation sequences

- Actively managing the critical path for electrical and mechanical systems

- Establishing clear escalation paths for utility, equipment, and permitting risks

- Using rolling look-ahead schedules to protect commissioning milestones

Projects that do this well can adjust early when risks appear instead of discovering problems at the end of the build.

2. Use Digital Tools to Control Field Execution

Digital tools only create value when they directly support field execution. Leading teams use BIM (Building Information Modeling), construction management platforms, and connected frontline worker platforms to:

- Identify and resolve clashes before materials arrive

- Connect drawings, RFIs, and change orders to the actual work being performed

- Track system-level progress, not just area or trade completion

- Assign tasks, enable collaboration and ensure safety in the field

- Enforce and document quality and regulatory compliance

The real payoff comes when the digital systems drive feed commissioning readiness. If teams know the status of every system in the project build, commissioning becomes more predictable rather than chaotic.

3. Treat QA/QC as a Production Control System

In data center construction, quality assurance and quality control are essential. QA/QC is not just paperwork — it is risk management.

Best-practice QA/QC programs include:

- Well-defined quality policies, procedures and systems for documentation

- Trained inspectors involved as work is performed

- Digital verification of critical tasks and equipment installation

- Digital inspections, photos, and digitized test records tied to each asset

Every defect that escapes early QA/QC multiplies in cost and delay during commissioning. Catching issues at the crew level is one of the most powerful ways to protect schedule and budget.

4. Design Safety into Work with High-Energy

Data centers introduce unique safety risks: high-voltage electrical systems, heavy mechanical equipment, pressurized piping, and confined spaces. Leading contractors treat safety as a core operating discipline, not a compliance function.

Best practices include:

- Task-based hazard analysis and energy-isolation planning

- Electrical safety boundaries and lockout/tagout enforcement

- Frontline safety leadership and regular safety stand-downs

- Digital hazard reporting and advanced AI-powered vision safety platforms

Embedding robust safety planning and strong adherence to safety protocols directly supports worker productivity and schedule reliability.

5. Coordinate Trades Like a Production Line

Data centers are built through tightly sequenced, multi-trade workflows. Power, cooling, controls, and commissioning activities must align precisely to avoid congestion, rework, and downtime.

Best-in-class job sites use:

- Weekly look-ahead schedules across all trades

- Daily field coordination meetings

- Clearly defined handoffs between installation and testing teams

- Frontline digital tools to streamline collaboration, task assignment and handoffs

This keeps work flowing smoothly and prevents critical systems from being blocked by out-of-sequence activity.

6. Invest in Workforce Capability

Modern data center construction demands skills beyond those of traditional commercial construction. Crews must understand high-voltage systems, precision cooling, control wiring, and commissioning readiness.

Leading organizations invest in:

- Targeted training aligned to data center systems

- Mentorship between senior and junior technicians

- Digital training tools for OTJ reference and upskilling

- Certification programs tied to real job-site requirements

A capable workforce installs faster, makes fewer errors, and accelerates commissioning — protecting both schedule and costs.

7. Enforce Cross-Functional Communication

The biggest project failures rarely come from bad design — they come from misalignment between teams.

Best practices include:

- Shared access to the same drawings, schedules, and system data

- Regular coordination between design, construction, and commissioning teams

- Tools to facilitate job site communication and collaboration in real-time

- Transparent reporting of system readiness and risk

Clear communication channels across team members involved in planning and design, construction execution and management help identify issues early and ensure problems are surfaced early, when they are still manageable.

Prepare for the Drivers of Cost & Schedule Risk

Understanding what drives risk is foundational to project planning and execution:

1. Utility Interconnection and Grid Delays

Securing power infrastructure and upgrades can take significantly longer than typical permitting cycles, often becoming the critical path for project delivery.

2. Equipment Lead Times

Key components such as switchgear, transformers, and HVAC systems can have lead times ranging from several months to over a year, affecting both the schedule and the cost.

3. Permit and Code Compliance

Multiple authorities having jurisdiction (AHJs) and overlapping regulatory frameworks increase unpredictability in scheduling and inspection cycles.

4. Labor Shortages and Rising Rates

Shortages in skilled labor not only extend schedules but also escalate labor rates, directly influencing data center construction costs.

5. Design Changes Late in Construction

Revisions during construction — particularly in power, cooling, or redundancy requirements — can result in rework and disruption at the site execution level.

How Digital Frontline Platforms Complete the Execution System

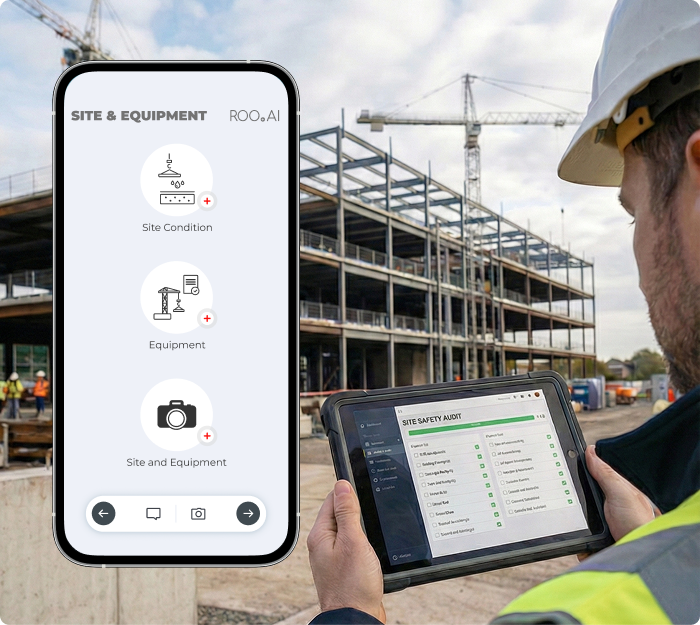

Even the best project plans, BIM models, and QA programs break down if the people doing the work can’t see, understand, and act on them in real time. This is where connected frontline worker platforms like ROO.AI become a force multiplier for data center construction teams. By putting work instructions, collaboration, QA checklists, safety procedures, and system status directly into the hands of construction workers, equipment operators, electricians, pipefitters, and supervisors, these platforms close the gap between planning and execution. Crews no longer rely on outdated paper prints, verbal instructions, or tribal knowledge — they work from a single source of truth that stays synchronized with project controls and design intent.

Just as importantly, frontline connected worker platforms create live feedback loops. As work is completed, tested, and inspected, that data flows back into project management, BIM, and commissioning systems. Leaders can see which systems are ready, where bottlenecks are forming, and where quality or safety risks are emerging — while there is still time to intervene. In an environment defined by aggressive schedules, complex systems, and razor-thin margins for error, digital frontline enablement isn’t a “nice to have.” It’s what turns best practices into repeatable, scalable performance across every data center build.