In industrial settings, where machinery and equipment pose inherent hazards, implementing robust lockout-tagout (LOTO) procedures is crucial for safeguarding the well-being of workers. In the realm of industrial safety, the lockout-tagout (LOTO) process stands as a cornerstone for preventing accidents during equipment maintenance and servicing. To optimize safety and compliance, organizations must adhere to best practices for executing LOTO processes effectively. With the advent of digital work instruction solutions on mobile devices, LOTO best practices can be more effectively enforced in several ways.

Enforcing Standardization

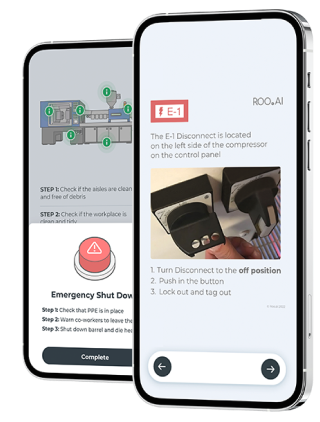

Digitalizing LOTO processes allows for the standardization of safety protocols, minimizing human error and ensuring consistency. Enabling workers with digital tools can enforce predefined workflows and procedures, guiding workers through the steps required to safely isolate energy sources and apply lockout devices. By standardizing LOTO procedures, organizations can mitigate the risk of procedural deviations that can increase the risk of accidents.

Continuous Training and Education

Ensuring ongoing training and education on LOTO procedures is crucial to reinforce knowledge and skills. Modern digital frontline platforms such as ROO.AI offer the opportunity to embed training and safety reminders in the flow of work, providing the workforce with in-context learning opportunities. Along with offering easier access to safety training on demand, digital frontline tools can facilitate improved toolbox talks, and scenario-based training exercises to help reinforce the importance of LOTO compliance and safety-consciousness.

Enhanced Documentation and Compliance

Digitalization facilitates comprehensive documentation of LOTO procedures, improving monitoring and compliance with regulatory requirements. Digital lockout-tagout workflows enable organizations to automatically capture equipment information, procedural verification using images and video, and generate digital audit trails of LOTO activities. This digitized documentation not only enhances accountability but also simplifies regulatory reporting and compliance assessments, reducing the risk of non-compliance penalties and fines.

Digitalize LOTO Best Practices

Digitalizing lockout-tagout processes offers a transformative approach to enhancing workplace safety, efficiency, and compliance. By leveraging digital solutions to automate procedures, reinforce safety training and improve documentation, organizations can elevate safety standards, reduce risks, and foster a culture of safety excellence. As manufacturers strive to embrace digital transformation initiatives, digitalizing LOTO processes emerges as a critical enabler for achieving safety objectives and safeguarding employee well-being in industrial environments.